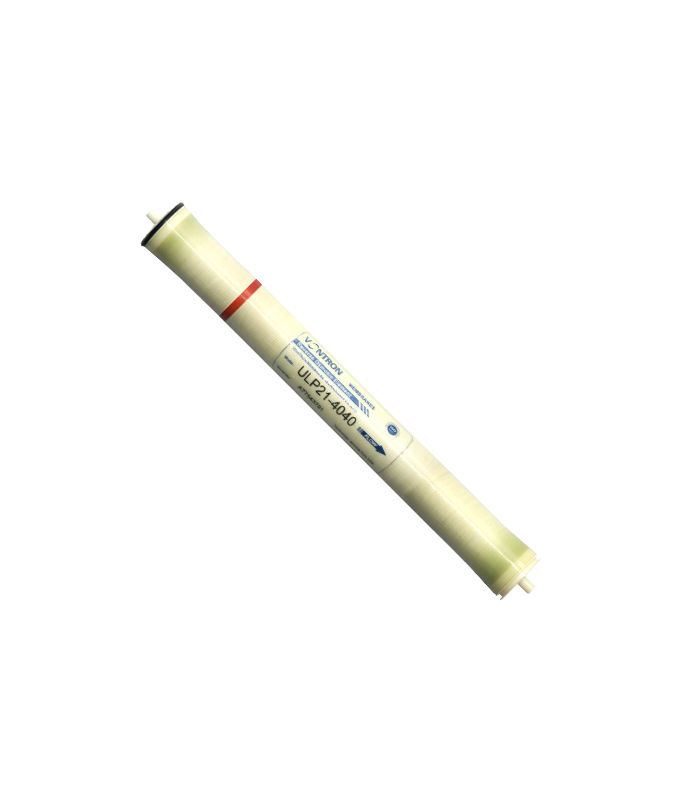

Vontron ULP & LP Membrane Elements: Efficient Water Desalination and Purification

Vontron Membrane Technology Co., Ltd. offers two distinct series of membrane elements, the ULP (Ultra-Low Pressure) and LP (Low-Pressure), designed for efficient water desalination and purification across various applications.

ULP Series: High Performance at Ultra-Low Pressure

The ULP series features newly developed ultra-low pressure aromatic polyamide compound membrane elements. These innovative membranes are engineered to operate at significantly lower pressures while delivering the same high permeate flow and rejection rates as conventional low-pressure membrane elements. This makes them particularly suitable for desalinating surface water and underground water, offering an energy-efficient solution.

LP Series: Versatile Low-Pressure Treatment

The LP series consists of low-pressure elements typically used for treating brackish water, surface water, underground water, and municipal water with a Total Dissolved Solids (TDS) concentration of less than 10,000 ppm.

These versatile membranes are primarily utilized in the production of:

Bottled water

Drinking water

Industrial pure water

High-purity water

Boiler replenishment water

Beyond these, the LP series is also effective for wastewater reuse, material concentration, purification, and refining processes.

Testing and Operational Guidelines

To ensure optimal performance and longevity, both series adhere to specific testing conditions and operational limits:

Testing Conditions:

Testing Pressure: 225 psi (1.55 MPa)

Temperature of Testing Solution: 25 °C

Concentration of Testing Solution (NaCl): 2000 ppm

pH Value of Testing Solution: 7.5

Recovery Rate of Single Membrane Element: 15%

Operation Limits & Conditions:

Maximum Working Pressure: 600 psi (4.14 MPa)

Maximum Feedwater Flow:

75 gpm (17 m³/h) for 8040 elements

16 gpm (3.6 m³/h) for 4040 elements

Maximum Feedwater Temperature: 45 °C

Maximum Feedwater SDI (Silt Density Index): 5

Residual Chlorine Concentration of Feedwater: < 0.1 ppm

pH Range of Feedwater during Continuous Operation: 3 to 10

pH Range of Feedwater during Chemical Cleaning: 2 to 12

Maximum Pressure Drop of Single Membrane Element: 15 psi (0.1 MPa)